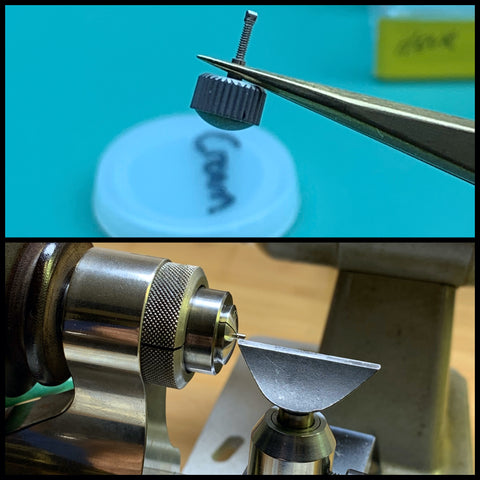

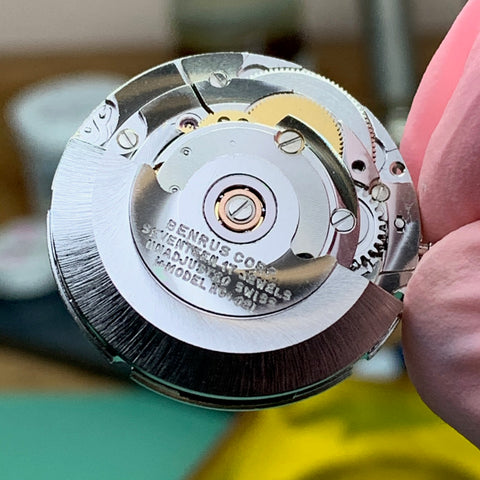

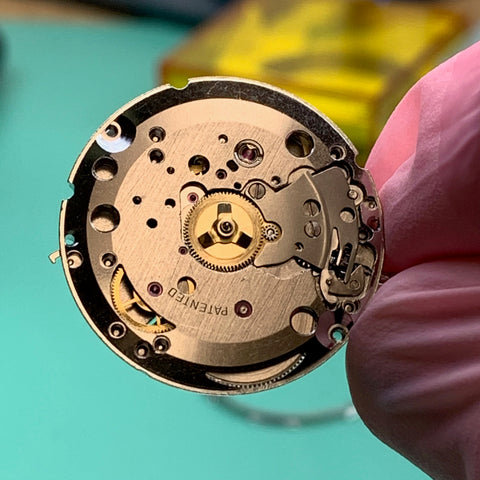

I recently serviced this 1970's Benrus Type I Class A military watch for the son of its original owner who served in the US military. These watches feature an innovative quality one-piece "monobloc" case, also referred to as a monique case. As with nearly all Swiss monobloc designs, it features a "split stem" which today is a common point of failure. The movement is removed through the crystal, not the back. The crown is yanked from the watch violently during servicing or, if you are fortunate and work with some skill, more gently removed from the case by tilting the movement out of the case. As a two-piece part with a joint in the middle, the crown stem fails after a long enough period of time from use or past servicing. Original parts aren't available and it's more work than it appears to produce a new two-piece stem to include work on the lathe and, in some cases, careful reaming and drilling of the existing case crown tube. If you are only sightly off in your cutting, you need to start all over again. This particular watch had a Benrus modified ETA 2821, a bit different than the typical versions I see. Also shown in the pictures are repairs to a setting part which had become dislodged due to past improper servicing and replacement of a worn rotor bearing. I also show a tool (yellow) for removing the bezel. Proper and safe bezel removal across a range of different cases requires an investment in quality tools to avoid the risk of damage. It's true that sometimes a cheap tool works depending on the case. However, to avoid damage while working on the range of fixed and rotating bezel designs, the professional approach is to use the best possible tools and techniques. The Bergeon tool shown features a limiter to prevent too much force on the bezel and protective plastic with thin lip for lifting-up and grasping the bezel. The watch is now running beautifully again with near COSC accuracy.