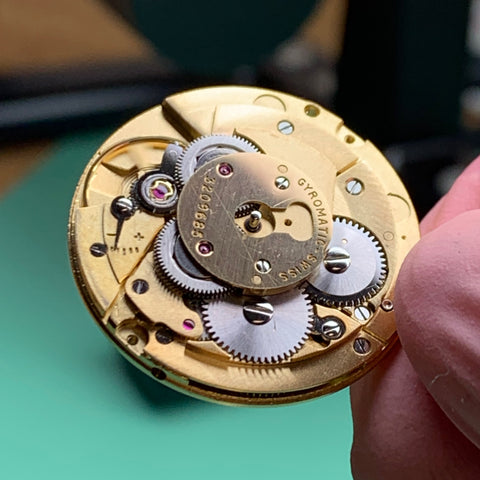

This is a beautiful tropical dial 1950’s Girard Perregaux calibre 32 from the heyday of automatic watch innovation. I recently serviced it for ClockSavant customer & fellow Instagrammer @nostalgic_principes (Will.) In 2017, he purchased it from a seller who sold it as “serviced” and, par for the course, it wasn’t. The watch had issues but was kept. Will was not yet a ClockSavant customer so he brought it to a local watchmaker who stated “it’s an old worn-out watch” and could not be serviced. Will then gave it to a large jeweler/watch dealer with a service center who works on modern and vintage watches. They walked-way from servicing it themselves and sent it to the factory in Switzerland. The factory offered to restore it but the cost was prohibitive for the watch (many times its value.) Will, now a customer, sent it to me. Cutting to the chase, it is in-fact a very nice watch; however, it uses an “offset cannon pinion” on the 3rd wheel of unusual design. Cannon pinions use friction for time setting and are routinely tightened. However, this design assumes the whole third wheel is replaced during servicing as the pinion was not designed to be removed and tightened. Today there is no option— devise a way to service it or walk away. The pinion was on very tightly but still lost friction. I spent some time studying the design and concluded there are many ways to destroy the wheel removing the pinion, but one candidate approach, treating the pinion as I would a roller table on a balance wheel, might work. In this case I used a last resort roller tool I have— it’s large and has less “controls” but it is ideal for large and unwieldy wheels. I was successful at removing the pinion. I then very carefully and strategically crimped it, shaped the nose of the pinion, lubricated, and reinstalled. Time setting “feel” was now perfect and after a good deal of testing, the victory flag was raised. The watch sailed through testing and is now performing beautifully once again.